Why Vectors are Key for Flawless Metal Engraving | Cre8iveSkill

Vector ArtA brand’s reputation often depends on the smallest details, like the tiny, perfectly formed logo found on the metal clasp of a designer watch or the frame of premium sunglasses. This miniature mark acts as a silent guarantee of authenticity, and its flawless execution is a direct reflection of the products quality. This type of high-fidelity branding is a pillar of the luxury goods industry, a key sector driving the laser engraving market toward its projected $4 billion valuation by 2026 (https://www.mordorintelligence.com/industry-reports/laser-engraving-machine-market).

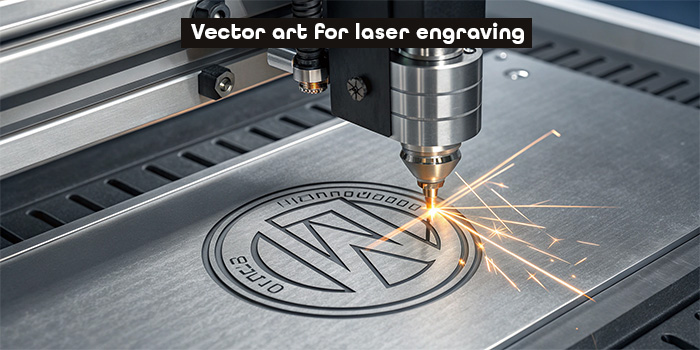

However, the secret to achieving this flawless result lies not in the powerful laser but in the quality of the initial design file. All these start with vector art for laser engraving, created in a high-resolution vector format like a high-quality SVG, to ensure the final mark has crisp, clean lines.

How High Resolution Vector Format Directly Affects Engraving Outcomes ?

.jpg)

A. Mathematical Precision Eliminates Errors:

The secret to the flawless results from high-quality SVG files lies in simple math. Instead of being a grid of pixels, every line and curve in a vector design is a perfect mathematical path. This completely removes the guesswork that lasers face when trying to read pixel-based images. The machine is no longer trying to connect the dots; its following a smooth, precise roadmap. A recent study found that vector-based designs slash cutting mistakes by 25% and can achieve precision up to 0.001 inches (https://ud.goldsupplier.com/blog/what-file-does-laser-cutter-use/).

This mathematical foundation guarantees that every single piece in a production run has the same sharp edges and perfect dimensions, making it absolutely essential for any metal engraving project that demands consistency and precision.

B. Design Flexibility Saves Time and Headaches:

You’re just about to start a big engraving job, and the client calls with a last-minute change. Maybe they want to tweak the text on an award, or they’ve decided the logo needs to be just a tiny bit larger. That’s the beauty of the flexibility you get when working with a professional vector art conversion service. Because the design is made of editable paths, you can easily change colors, adjust dimensions, or refine small details without losing any quality. This ability to make on-the-fly adjustments is a lifesaver. For example, if a test engraving on a new type of metal doesnt look quite right, you can instantly make the lines thicker and run it again. This freedom to iterate and perfect your design is what consistently leads to amazing final results.

C. Scalability Maintains Quality Across All Project Dimensions:

One week, you need your logo flawlessly engraved on a batch of small, metal bottle openers for a promotional event. Next, you need it on the larger, polished tap handles behind the bar. A month later, you’re ready for the big one: a massive metal sign to hang above the entrance.

With a single vector file, you can handle all three jobs perfectly. The logo on the huge sign will be just as crisp and sharp as the one on the tiny bottle opener. Its just like a digital rubber band; you can stretch it or shrink it, and the lines stay perfectly smooth because the design is built on math, not pixels. Professional engravers confirm the huge time savings from using one file for multiple projects

sizes (https://www.xtool.com/blogs/xtool-academy/raster-vs-vector-engraving).

A professional PNG to vector high quality conversion turns a simple art into a versatile, powerful asset that’s ready for any project you can dream up, big or small.

D. Speed Optimization Transforms Production Efficiency:

An order for 100 engraved metal plaques might take hours with a raster file, but with vectors, that same job could be finished in under an hour. To understand why, lets look at how the laser operates. When engraving a pixel-based image, the machine moves back and forth across the entire design area, much like an inkjet printer, filling it in line by line. With a vector file, however, the laser takes a more intelligent path, simply and swiftly tracing the outlines of the design.

A test by Trotec highlights this perfectly: an identical design took 3 minutes and 9 seconds to engrave as a raster file, but was completed in just 19 seconds as a vector (https://www.troteclaser.com/en/resources/blog/optimizing-efficiency-and-line-thickness-with-vector-engraving).

This is where a professional vector art conversion service plays a crucial role. It doesn’t just convert a file; it delivers an optimized design that enables you to process more orders each day, offer quicker turnarounds, and confidently accept last-minute rush jobs.

E. Speed Optimization Transforms Production Efficiency:

And last but not least, vectors take up significantly less storage space and require less processing power than a comparable pixel-based image. This means your computer and engraving machine can run much more smoothly, helping to reduce those frustrating production bottlenecks. Plus, because the file sizes are so small, sending them from the design team to the production floor is quick and easy, helping to cut down on workflow delays and keep your projects on schedule.

Pro Tips for Perfect Engraving with a High Resolution Vector Format.

A. Leverage Resolution Settings for Project Goals:

The key to great results is finding the perfect sweet spot between incredible detail and fast production speed. For general-purpose jobs like industrial marking, a moderate 300 DPI will give you crisp, quick results. If your project involves logos or fine text, bumping it up to 400 DPI is a great choice that sharpens the edges without adding much time. You should only reserve the full 600 DPI for special projects where those tiny micro-details will be seen up close.

B.Implement Template-Based Batch Workflows:

If you often engrave big batches of the same item—like a whole sheet of nameplates, serial tags, or branded parts—a huge time-saver is to create a master template that fills the entire engraving area.

To make this process even smoother, you can build helpful guides directly into your vector file. By including "registration marks" and grouping different tasks by color in your design, you tell the laser exactly where to go and what to do.

C. Partner with a Reputable Vector Art Conversion Service Provider:

Expert services manually trace a design, carefully cleaning it up by smoothing out lines, fixing any messy spots, and removing overlapping paths. The goal is to deliver a fully optimized high-resolution vector format file that is built to work perfectly with laser engraving machines.By partnering with a conversion specialist, you get your files back quickly and can be sure your branding looks exactly right. Most importantly, you gain the confidence of knowing every file is truly “laser ready,” which is the final step in guaranteeing a flawless finished product.

The Bottom Line:

In the end, that flawless, crisp engraving on metal isn’t just about the laser—its about the blueprint it follows. A high resolution vector format is what guarantees every line is sharp and every detail is perfect. Whether youre creating fresh vector art for laser engraving or need a professional png to vector high quality conversion, starting with a flawless file is non-negotiable.