Why High-Quality Vector Files Are Non-Negotiable for Glass Engraving Suppliers?

Vector ArtWe all know what’s happening in glass engraving lately—its honestly mind-blowing. The industry is in a full-on precision revolution, where the lasers we use can etch details so fine they’re almost invisible to the naked eye. But here’s the frustrating part we’ve all dealt with: you can have the best equipment in the shop, yet an entire job gets held up by a fuzzy, low-quality file from a client. It’s a classic bottleneck that leads to project delays and having to quote for a vector art conversion service. Its a real headache for workflow.

So, whats the secret to a smoother process? High-quality vector files. They are the non-negotiable foundation for getting that razor-sharp finish your clients expect. In this post, we’re going to break down exactly what they are and why they are the only choice for a flawless final product.

Why Is Micro-Level Precision Essential for Glass Engraving?

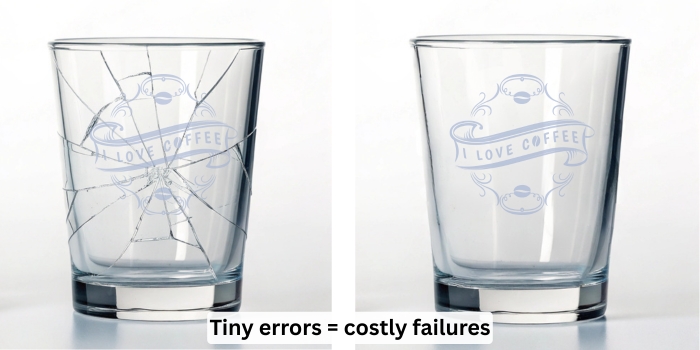

Were talking about a level of detail where being off by just ±0.001mm can mean the difference between a professional masterpiece and a costly failure. For glass engraving suppliers and related businesses, understanding these precision requirements is crucial for delivering high-quality pictures engraved into glass and maintaining competitive advantage in todays demanding market.

A) Glass Doesnt Forgive Mistakes:

Theres nothing worse than watching a $200 custom piece turn into expensive trash because the lasers focus was slightly off. For thin glass applications, like wine glasses, ornaments, and detailed pictures engraved into glass, this precision becomes even more critical since theres less material to absorb the lasers energy. Glass has unique thermal properties that make micro-level precision absolutely essential for preventing structural damage. The thermal stress from the laser requires incredibly precise power delivery and focus control (https://www.rsd-laser.com/newsinfo/958446.html).

When the lasers power or positioning varies beyond these micro-tolerances, the glass can develop microfractures that spread into visible cracks, ruining the piece. This is why maintaining consistent depth control is so important—it’s what prevents breakthrough damage on these delicate surfaces.

B) Superior Precision Capabilities:

For you, the work isnt finished when the hum of the laser fades. In fact, what comes next is what separates the pros from the amateurs: the final quality check. This is where technicians get hands-on, using precision measurement tools to verify that every single detail on the finished piece is perfect. This meticulous final step is what proves the value of starting with a perfect vector file. It ensures that complex glass engraving images or precise corporate logos are flawlessly reproduced on every single item in a batch. Ultimately, for a supplier, this rigorous quality assurance is your reputation in physical form.

C) Critical Tolerance Requirements Drive Quality Standards:

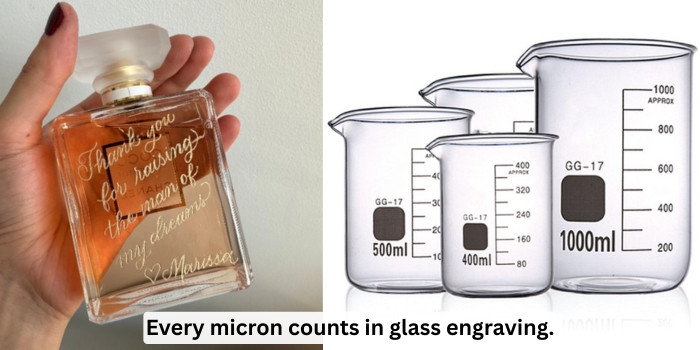

Modern glass engraving operations require tolerances ranging from ±0.001 mm to ±0.005 mm depending on application complexity. UV laser systems designed for precision achieve marking precision as tight as ≤0.001 mm with minimum line widths of 0.01 mm, ensuring every micron counts for clarity in glass engraving (https://algolaser.com/blogs/how-to/prepare-your-vector-files-for-laser-engraving). This level of control is what makes it possible to flawlessly engrave a delicate logo onto a perfume bottle or etch hyper-detailed measurement lines onto scientific glassware, where accuracy is everything. Furthermore, professional laser systems offer a repetition accuracy of 0.001 mm, ensuring the first piece and the thousandth piece in a batch look absolutely identical. For any glass engraving supplier, this means getting the job done right the first time, leading to less wasted material, happier clients, and a reputation for quality.

D) Competitive Differentiation Through Precision Standards:

Imagine a corporate client comes to you with a tight deadline, ordering 500 crystal tumblers. This high-stakes situation is where a laser engraver vector workflow becomes a true competitive advantage for your business. Instead of guessing with pixels, vectors provide a perfect roadmap for the laser, ensuring every logo has razor-sharp edges and all text is spaced perfectly, no matter the size.

This precision means you waste less time on test runs and prevent common mistakes like messy, overlapping lines, delivering consistent quality even on tricky curved pieces. So, whats the end result for you? Its a clear edge over competitors who still rely on raster files. It means faster, more predictable turnarounds, less wasted material, and a premium finish on every single item. This is what gives you the confidence to take on complex, high-margin jobs, quote tighter deadlines, and ultimately, command a premium price for guaranteed, top-tier quality.

The Essential Vector Tips for Every Glass Engraving Job.

A) Preflight and Clean Your Vector Geometry:

Before any engraving work, its crucial to thoroughly inspect every vector file. You need to check for any hidden issues: close all open paths, remove overlapping or duplicate lines, and join any broken segments. You also need to simplify areas with too many nodes, expand strokes where needed, and correct any compound-path knockouts. Clean geometry ensures the software controlling your laser engraver vector paths creates a perfect, single-pass toolpath.

B) Design for Glass and Fixture Constraints:

Another smart move is to incorporate rounded inner corners and give features some safe spacing in your design. When youre ready to engrave, planning for multiple light passes instead of one heavy one is key—this helps prevent thermal stress, which can cause those tiny, frustrating microfractures.And for those tricky cylindrical or irregular items, the setup is everything. You’ll want to properly calibrate your rotary axis and focus offset. Using the right jigs or soft pads is also a must to stop any slippage and vibration. It’s these details that ensure every picture engraved into glass comes out perfectly aligned and flawless.

C) The Smart Outsource:

When youre facing a difficult client file or a tight deadline, partnering with a reputable vector art conversion service can be a game-changer.

They deliver print-ready vector files that are hand-drawn and optimized by experts. This means the artwork you get back has proper line weights, closed paths, and clean geometry, eliminating those frustrating pre-production delays. The real advantage is that your team can focus on production, while you guarantee technically perfect artwork for every job.

The Bottom Line:

At the end of the day, flawless glass engraving isnt just about having the best machine—its about feeding it a perfect file. A clean laser engraver vector path is your blueprint for success, ensuring every project runs smoothly and your final product looks absolutely stunning.

For those tough client files or complex glass engraving images, that’s where a trusted partner makes all the difference. At Cre8iveSkill, our expertise is in our Vector Art Conversion Service. We turn any concept into a perfect, print-ready vector format, ensuring all your pictures engraved into glass have the crisp, professional quality your clients demand.